CONTACT INFO

Tel:4006590306

E-mail:admin@yihuatrade.com

Chromium carbide overlay wear-resistant plate

- Commodity name: Chromium carbide overlay wear-resistant plate

Category

Contact Info

Product Details

Overview

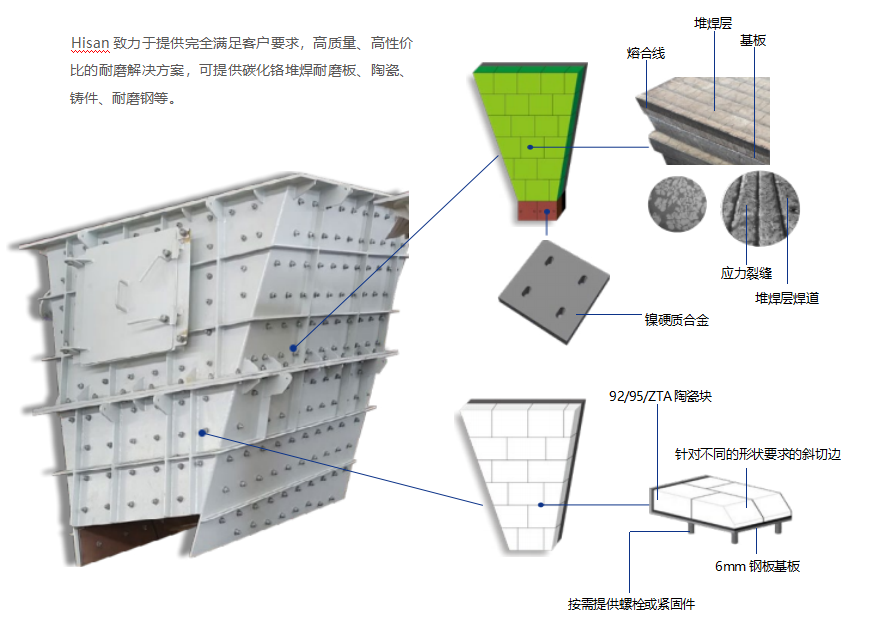

Hardfacing plates are manufactured by cladding wear-resistant materials onto a carbon steel substrate. A large number of carbides are fused onto the substrate and evenly distributed throughout the hardfacing layer thickness, forming a bimetallic material with high wear resistance and good machinability. The low-carbon steel substrate can be welded or bolted, and the hardfacing layer has excellent wear resistance, ensuring extended equipment life and durability, and reducing maintenance costs.

Product Range

| Product Name |

General Description |

| HS100 |

HS100 performs excellently in severe wear and low to medium impact environments. |

| HS200 |

HS200 performs excellently in severe wear and low to medium impact environments. |

| HS300 |

HS300 is suitable for applications involving high wear and medium to high impact. |

| HS600 |

HS600 is suitable for extremely severe wear applications. |

| HS-F |

Smooth surface plates are suitable for applications with high wear and plugging. |

| HS-X |

HS-X wear-resistant plates can be customized according to customer requirements. |

Size

| Standard Plate Size (mm) |

1400*3000 |

1500*3000 |

1400*3700 |

2000*3000 |

| Coating Thickness (mm) |

3-80 |

|||

| Base Material Thickness (mm) |

3-150 |

|||

| Other sizes and thicknesses are available upon request. |

||||

Features

A large number of primary chromium carbides are evenly distributed.

A large number of primary chromium carbides are evenly distributed.

Good flatness.

Good flatness.

Macrohardness: 57-63HRC.

Macrohardness: 57-63HRC.

Various grades are available for different applications.

Various grades are available for different applications.

Excellent wear resistance (ASTM G65 Procedure A).

Excellent wear resistance (ASTM G65 Procedure A).

Large plate width improves material utilization.

Large plate width improves material utilization.

Uniform positive tolerance thickness.

Uniform positive tolerance thickness.

Good machinability due to uniform stress relief in the hardfacing layer

Good machinability due to uniform stress relief in the hardfacing layer

Elements

| Elements |

C |

Si |

Mn |

Cr |

Mo, Nb, Ni, Ti, V, W, B, etc. |

Other |

| Content |

3-7.5% |

0.5-3.0% |

0.5-3.0% |

20-40% |

As Required |

Balance |

Manufacturing

The backing plate provides structural integrity for Hisan plates, which allows our hardfacing plates to be manufactured without damaging the hardfacing layer, regardless of shape and complexity. Hisan is capable of manufacturing finished wear parts, including:

Applications

| Industry |

Applications |

| Mining |

Bucket wheel excavators, bulldozer blade liners, truck body liners, power shovel bucket liners, front-end loaders, scraper conveyors, dragline bucket liners, screw conveyors, crusher liners, hopper liners, chute liners, bin liners, screens, pipes, pumps, etc. |

| Cement |

Cement mixers, fan blades, guide vanes, hoppers and chutes, conveyors, separator cones, cyclone separator shells, fan impellers and housings, roller presses, screens, pipes and elbows, vertical mills, crusher liners, mill body liners, feed chutes, bell housings, dust collectors, scrapers, grinding rollers, grinding plates, mill housings, etc. |

| Power Plants |

Chute and hopper liners, fan blades, crushers, fuel transfer pipes, separation cones, boiler pipes, burner hoppers, inlet and outlet chutes, transfer points, screens, mill body liners, internal cones, coal feed pipes, separator body liners, hot air pipes, guide vanes, ash discharge pipes, pipes and elbows, grinding plates and roller hardfacing, etc. |

| Port |

Hoppers, chutes, discharge pipes, stackers and reclaimers, dredging ship conveying pipes, screw conveyors, conveying pipes, bucket wheel liners, power shovel liners, conveyor liners, bin liners, grab unloaders, continuous unloaders and bucket chain unloaders, etc. |

| Steel Plant |

Hoppers and chutes, screens, sintering machines, coke distribution cones, flue gas pipes, screw feeders, sintering machine discharge plates, vibrating conveyors, sintering machine feed channels, distribution chutes, sintering crusher parts, charging cars, top bell covers, rolling mill sliding dampers, slats, feeder bins, pipes and elbows, etc. |

| Bulk Material Handling |

Hoppers, conveyor chutes, grab bucket unloaders, stackers and reclaimers, truck loading silos, loading equipment, rotary chutes, suction pipes, discharge pipes, elbows, pipes, dredging pumps, etc. |

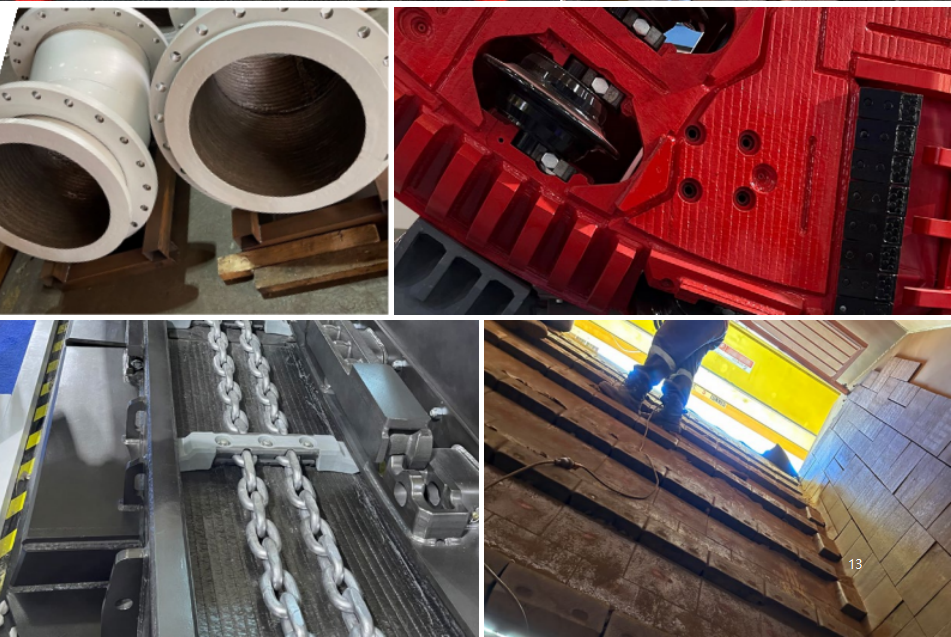

Application Cases

Keywords: Chromium carbide overlay wear-resistant plate

Recommended Products