CONTACT INFO

Tel:4006590306

E-mail:admin@yihuatrade.com

High chromium cast iron

- Commodity name: High chromium cast iron

Category

Contact Info

Product Details

High Chromium Cast Iron

The excellent wear resistance of high chromium cast iron is mainly due to the high volume fraction of very hard and well-dispersed carbides in the martensitic matrix. Controlling the microstructure to maximize wear resistance, the presence of carbides, and the fatigue resistance and toughness of high chromium cast iron all play an important role in its wear resistance.

Wear-resistant Block

Wear-resistant blocks can withstand impact and abrasion and provide superior wear life in a variety of industrial applications. They are commonly used in equipment and machinery with continuous surface wear.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| HSC200 |

200

|

25

|

15

|

10

|

25

|

1.0

|

|

| HSC300 |

300

|

25

|

15

|

10

|

25

|

1.5

|

|

| HSC153 |

153

|

38

|

25

|

8

|

33

|

1.5

|

|

| HSC300A |

300

|

38

|

25

|

8

|

33

|

3.0

|

|

| HSC203 |

203

|

50

|

12

|

8

|

20

|

1.6

|

|

| HSC254 |

254

|

50

|

12

|

8

|

20

|

2.0

|

|

| HSC190 |

190

|

50

|

20

|

10

|

30

|

2.2

|

|

| HSC190A |

190

|

50

|

20

|

10

|

30

|

2.2

|

|

| HSC65 |

65

|

50

|

38

|

12

|

50

|

1.3

|

|

| HSC115 |

115

|

50

|

38

|

12

|

50

|

2.3

|

|

| HSC127 |

127

|

50

|

38

|

12

|

50

|

2.4

|

|

| HSC150 |

150

|

50

|

40

|

10

|

50

|

2.9

|

|

| HSC190B |

190

|

50

|

40

|

10

|

50

|

3.7

|

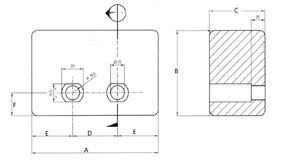

Wear-resistant Button

Wear-resistant buttons are designed for easy and adaptive installation in a wide range of wear problem areas to prevent wear at localized failure points. It is ideal for smaller areas requiring less welding time and material.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| WB60 |

60 |

40 |

20 |

10 |

30 |

0.7 |

|

| WB75 |

75 |

55 |

20 |

10 |

30 |

1.0 |

|

| WB75-27 |

75 |

55 |

17 |

10 |

27 |

0.9 |

|

| WB90 |

90 |

70 |

20 |

10 |

30 |

1.5 |

|

| WB90-32 |

90 |

70 |

20 |

12 |

32 |

1.6 |

|

| WB115 |

115 |

95 |

20 |

12 |

32 |

2.6 |

|

| WB150 |

150 |

130 |

25 |

16 |

41 |

5.7 |

|

| WB150-32 |

150 |

130 |

20 |

12 |

32 |

4.5 |

|

| HSC65 |

65 |

50 |

38 |

12 |

50 |

1.3 |

Chocolate Block

Chocolate Block: Metallurgically bonded martensitic white iron, bonded to a weldable, impact-resistant substrate. It provides superior wear and impact resistance and is easy to use and install.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| CB25 |

240 |

25 |

15 |

8 |

23 |

0.90 |

|

| CB40 |

240 |

40 |

15 |

8 |

23 |

1.50 |

|

| CB50 |

240 |

50 |

15 |

8 |

23 |

1.90 |

|

| CB65 |

240 |

65 |

15 |

8 |

23 |

2.50 |

|

| CB90 |

240 |

90 |

15 |

8 |

23 |

3.50 |

|

| CB100 |

240 |

100 |

15 |

8 |

23 |

3.90 |

|

| CB130 |

240 |

130 |

15 |

8 |

23 |

5.15 |

|

| CB150 |

240 |

150 |

15 |

8 |

23 |

6.20 |

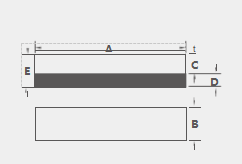

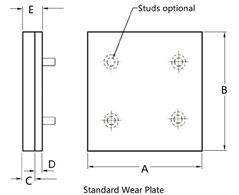

Wear-resistant Plate

Wear-resistant plates combine high-chromium wear-resistant white iron plates with weldable, high-impact toughness low-carbon steel plates through vacuum brazing to provide maximum impact and wear resistance.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| WP190 |

190 |

190 |

15 |

8 |

23 |

6.80 |

|

| WP200 |

200 |

404 |

15 |

8 |

23 |

14.80 |

|

| WP245 |

245 |

495 |

15 |

8 |

23 |

21.95 |

|

| WP390 |

390 |

390 |

15 |

8 |

23 |

27.60 |

|

| WP404 |

404 |

404 |

15 |

8 |

23 |

29.70 |

|

| WP495 |

495 |

495 |

15 |

8 |

23 |

44.50 |

|

| WP500 |

500 |

395 |

15 |

8 |

23 |

35.70 |

|

| WP505 |

505 |

300 |

15 |

8 |

23 |

27.50 |

|

| WP600 |

600 |

300 |

15 |

8 |

23 |

32.60 |

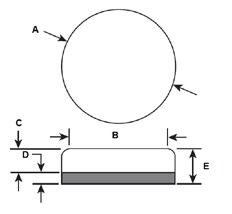

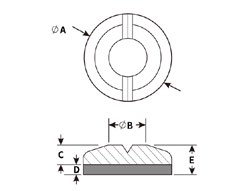

Wear-resistant Ring

Wear-resistant rings are ideal for quick repairs to localized wear problem areas. A variety of sizes make them ideal for small, awkward areas requiring wear protection.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| HSD75 |

75 |

25 |

17 |

8 |

25 |

0.7 |

|

| HSD100 |

100 |

50 |

17 |

8 |

25 |

1.0 |

|

| HSD100A |

100 |

70 |

24 |

8 |

32 |

1.0 |

|

| HSD130 |

130 |

80 |

15 |

8 |

23 |

1.3 |

|

| HSD148 |

148 |

108 |

25 |

10 |

35 |

2.2 |

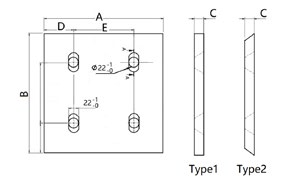

Nickel Hard Facing Plates and Blanks

Nickel hard cast iron products can be custom designed to meet any operating conditions, regardless of size and shape. Nickel hard cast iron is the perfect material for chute, bin, and hopper linings. We are happy to help you choose the right material grade for your specific operating conditions.

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| HL1 |

1 & 2 |

300 |

20 |

75 |

150 |

13.60 |

|

| HL2 |

1 & 2 |

300 |

20 |

75 |

150 |

9.20 |

|

| HL3 |

1 & 2 |

300 |

20 |

75 |

150 |

6.80 |

|

| HL4 |

1 & 2 |

300 |

20 |

75 |

150 |

5.40 |

|

| HL5 |

1 & 2 |

300 |

20 |

75 |

150 |

4.50 |

|

| HL6 |

1 & 2 |

200 |

20 |

62.5 |

75.0 |

3.10 |

|

| HL7 |

1 & 2 |

296 |

32 |

73 |

|

10.60 |

|

| HL8 |

1 & 2 |

296 |

32 |

98 |

|

14.30 |

|

| HL9 |

1 & 2 |

296 |

32 |

73 |

150 |

21.70 |

|

| HL10 |

1 & 2 |

300 |

32 |

150 |

75 |

10.90 |

|

| HL11 |

1 & 2 |

300 |

32 |

150 |

75 |

22.30 |

| Model |

A |

B |

C |

D |

E |

Weight (kgs) |

|

| HB299 |

299 |

150 |

100 |

152 |

40 |

35.00 |

|

| HB222 |

222 |

150 |

100 |

76 |

40 |

26.00 |

|

| HB146 |

146 |

150 |

100 |

76 |

40 |

17.00 |

|

| HB70 |

70 |

150 |

100 |

0 |

40 |

8.00 |

Application

Bimetallic Casting:

With superior wear resistance, it provides high wear protection under some of the harshest conditions, extending the service life of excavator, power shovel, wheel loader bucket, chute, bin, hopper, or crusher liners.

Nickel Hard Cast Liners and Blanks: Nickel hard cast products encompass a group of alloyed white cast irons ensuring high wear resistance in applications within the mining, mineral processing, construction, earthmoving, asphalt, and cement industries.

Keywords: High chromium cast iron

Recommended Products