CONTACT INFO

Tel:4006590306

E-mail:admin@yihuatrade.com

Hardfacing wear-resistant pipe

- Commodity name: Hardfacing wear-resistant pipe

Category

Contact Info

Product Details

Overview

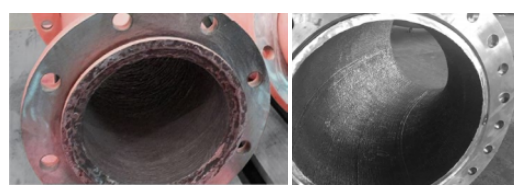

The design of hardfaced wear-resistant pipes can withstand the hardest and most abrasive materials, thus extending their service life. Hardfacing welding forms a wear-resistant layer composed of a large amount of chromium carbide, providing high hardness. It is an ideal wear solution for extreme applications with maintenance issues. It combines severe wear resistance and moderate to low impact resistance.

Specification

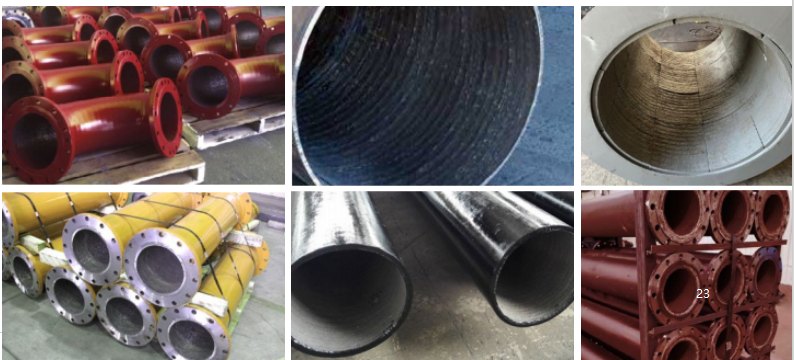

A variety of base pipe thickness and hardfacing layer thickness options are available. Lengths up to 40 feet. Minimum diameter of 3 inches.

End Fitting Options

There are many options for end fittings:

Standard flanges (i.e., 150#, 300#, and 600#) welding rings, Victaulic rings, etc.

Applications

Hardfaced wear-resistant pipes have been widely used in the steel, cement, concrete, mining, metallurgy, power generation, aggregate, glass, pulp, paper, and chemical industries.

It is the preferred choice for conveying materials such as: aggregates, ash, coal, sand, cement, stones, gravel, limestone, magnetite, scale, tailings, ores, raw material kiln feed, slurry, mud, and slag.

Keywords: Hardfacing wear-resistant pipe

Recommended Products